Medieval helmets consist of many elements. Depending on the type of the helmet, these elements can include: a dome (the main part), a visor, eye-slots, a comb, hinges, vervelles, fastenings and nails, as well as decorations. Each element has its own history and purpose. Visor hinges let you open and close visored helmets such as Klappviser Bascinet. There are a couple ways to make hinges. In our work we like to combine ancient and modern technologies.

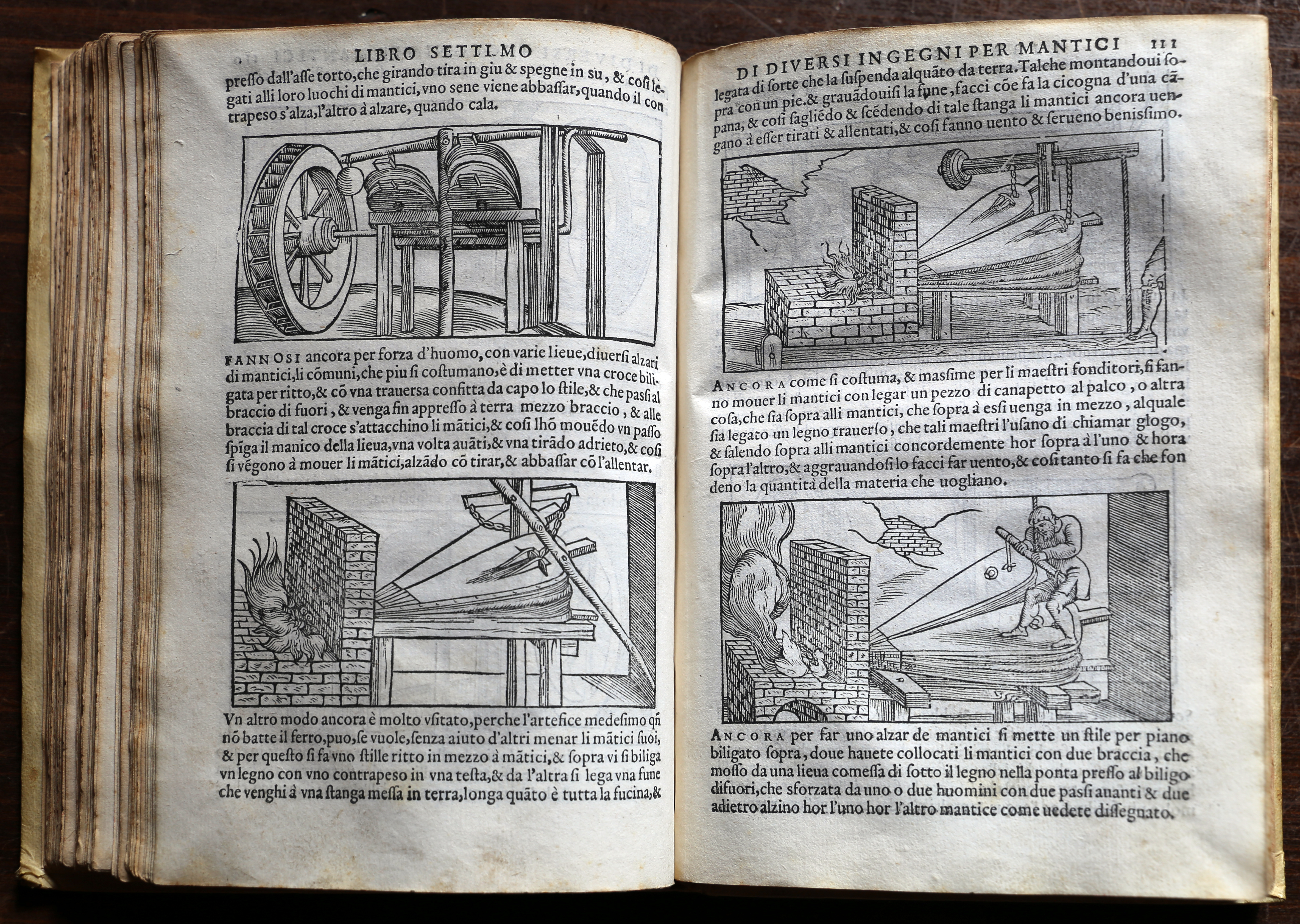

Sand molded casting is a very old technology. It was used in China in 1300 B.C.E. In Europe this method was described by the Italian scientist Vannoccio Biringuccio in his book “De La Pirotechnia” first published in 1540 in Venice.

The necessity of equipping troops in Europe with inexpensive, quickly produced armor led to the development of armor craft productions. The division of labor was an effective way to produce armor and helmets much faster than had been done previously. In their work, blacksmiths used casting methods as well as forge welding.

Before polymers were invented, people used natural materials such as bees wax to make a sand mold. Melted metal burns out the wax and gets the shape of the wax pattern. At the Forge of Svan we make extensive use of 3-D modeling. Instead of beeswax, we prefer to work with 3-D printed models.

We’re glad to be able to share with you the process of how armor goes through all the manufacturing steps to become your helmet or body harness. Choosing steel armor from Forge of Svan, you can be sure you’ll get well-made armor in the nick of time.

Shop

Shop